Unlocking Operational Excellence: A Deep Dive into Industrial IoT AI Agents

January 13, 2026

Introduction: The Next Evolution of Industrial IoT

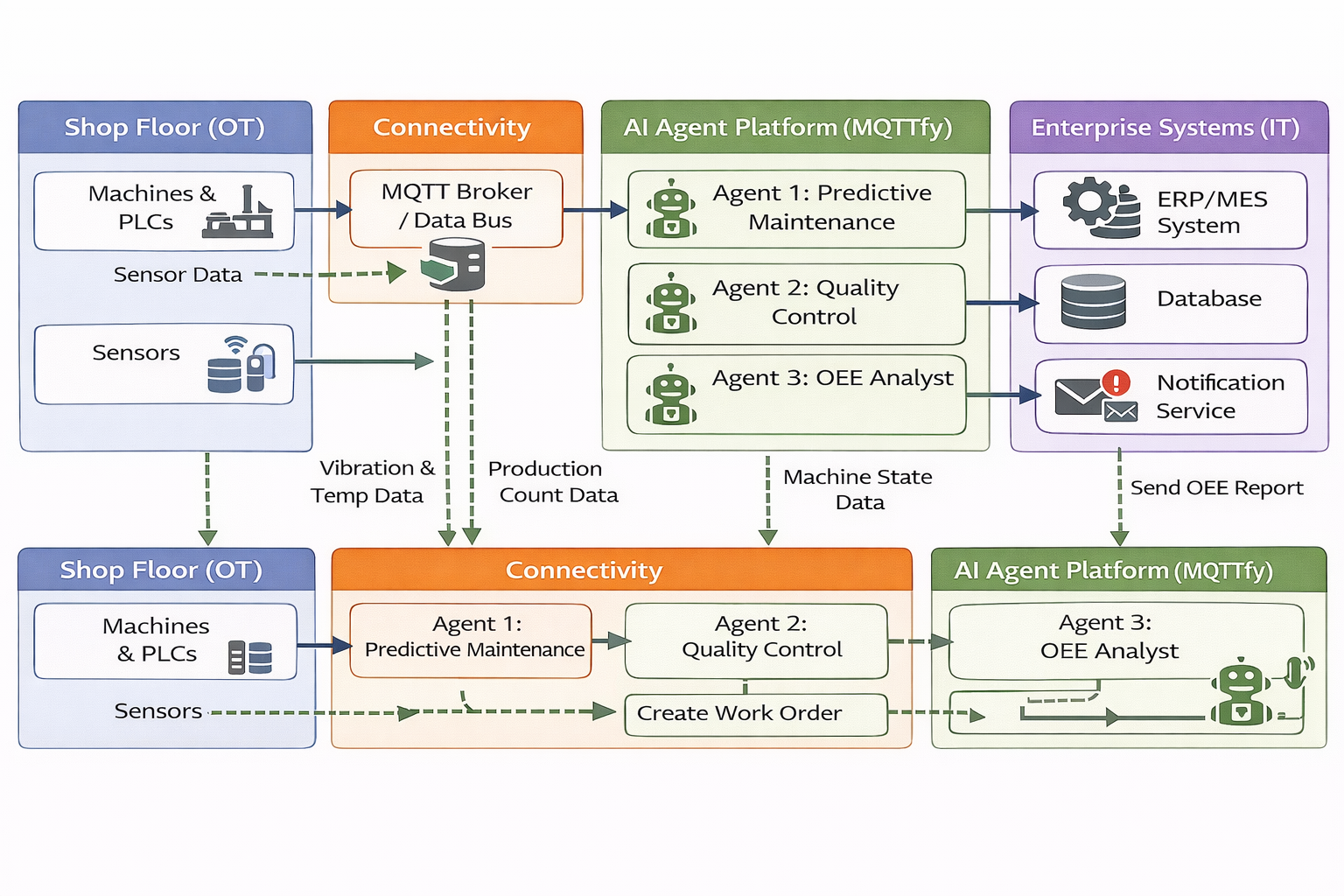

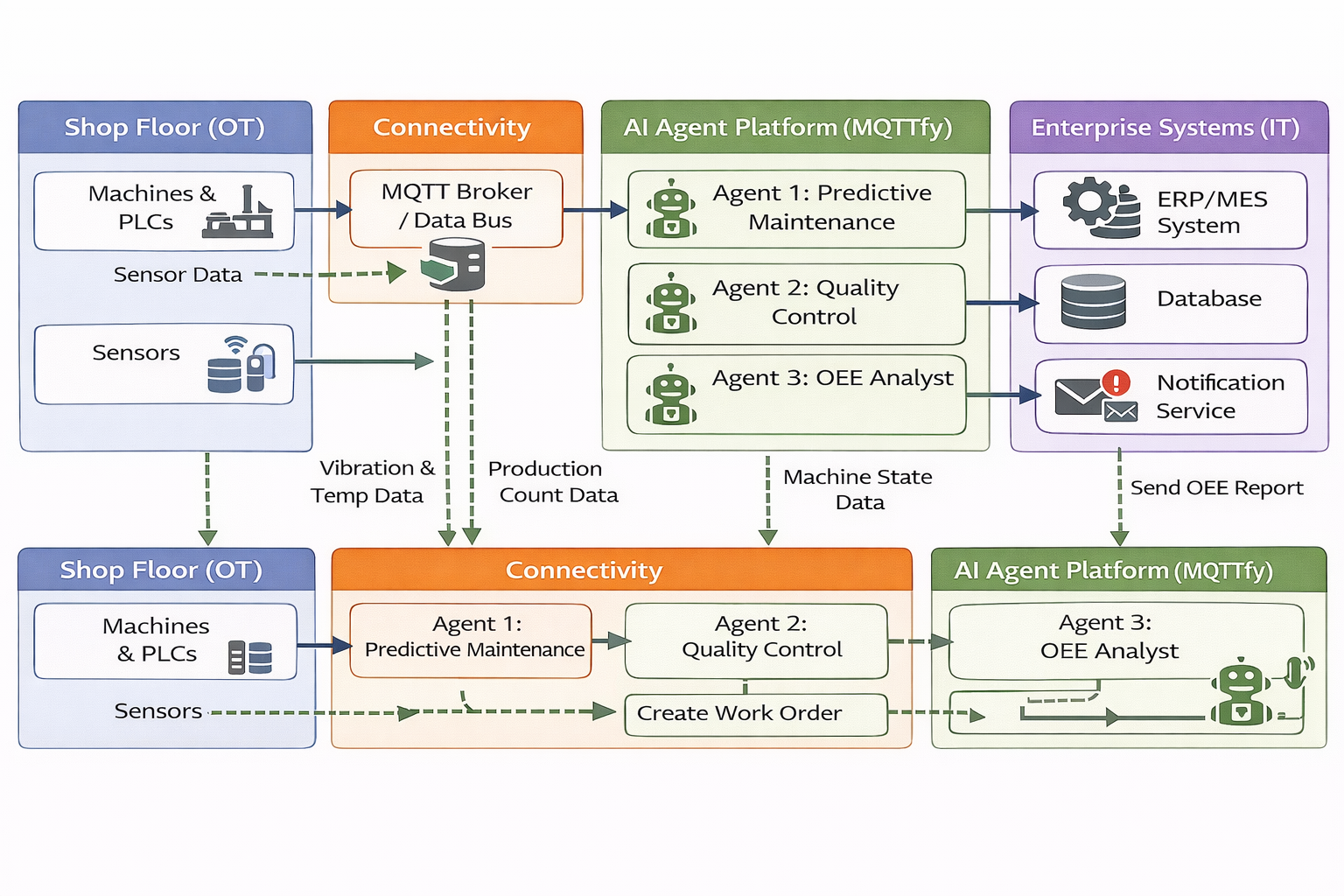

For years, the promise of the Industrial Internet of Things (IIoT) has been centered on data. We've connected sensors to machines, aggregated data in the cloud, and visualized it on dashboards. While this has provided unprecedented visibility into operations, it represents only the first step. The true revolution begins when we move from passive data visualization to active, autonomous decision-making.

This is the domain of the Industrial IoT AI Agent.

An IIoT AI Agent is more than just a dashboard or an analytics script; it is an autonomous digital worker with a specific goal, a set of skills (tools), and the intelligence to use them. It doesn't just show you that a machine's temperature is high; it understands the implication of that high temperature, correlates it with other data points, decides on the best course of action, and executes it—all without human intervention.

This article is an advanced guide for engineers, architects, and operations managers on how to design, build, and deploy these intelligent agents using a modern platform like MQTTfy. We'll explore the core architectural principles, a practical implementation workflow, and the profound impact these agents can have on operational excellence.

Core Concepts: What Makes an IIoT AI Agent?

To understand their power, we must first define what separates an AI Agent from traditional monitoring systems. An agent-based architecture is built on three pillars:

-

Goal-Oriented: Every agent is given a clear, high-level objective in natural language. This is its "system prompt." Instead of programming rigid

if-then-elselogic, you define the desired outcome.- Poor:

IF temperature > 90°C AND vibration > 0.5g THEN send_email("alert@company.com") - Better (Agent Goal):

"You are a predictive maintenance agent. Your goal is to prevent equipment failure. If you detect sensor readings that indicate a high probability of failure, create a high-priority work order in the maintenance system."

- Poor:

-

Tool-Driven: An agent is inert without its tools. "Tools" are a curated set of capabilities you grant the agent. These are secure, sandboxed functions that allow the agent to interact with the real world. Common tools include:

- Connecting to an MQTT broker to subscribe to or publish data.

- Making API calls to an Enterprise Resource Planning (ERP) or Manufacturing Execution System (MES).

- Querying a SQL database or a data historian.

- Sending notifications via email, SMS, or platforms like Slack.

-

Autonomous Reasoning: This is the AI core. When an agent is triggered by an event (e.g., new MQTT data), it uses a large language model (LLM) to analyze its Goal, the incoming Data, and its available Tools. It then autonomously decides: "Based on my goal, does this new data require me to act? If so, which of my tools is the right one for the job, and what parameters should I use?"

Architectural Shift: From Centralized Logic to Distributed Agents

This model represents a significant architectural shift. Instead of a monolithic application with complex, hard-coded business logic, you deploy a fleet of smaller, specialized agents.

This distributed, agent-based approach is inherently more scalable, resilient, and adaptable than traditional systems. Adding a new capability doesn't require rewriting a large application; you simply deploy a new agent with its own unique goal and tools.

A Practical Implementation: Building a Predictive Maintenance Agent

Let's walk through building a Predictive Maintenance agent using MQTTfy's visual editor.

Objective: We want an agent that monitors a CNC machine's spindle vibration and temperature. If both metrics cross a warning threshold, we want it to check the machine's current job status from the ERP system. If the machine is running a high-precision job, the agent should immediately shut it down to prevent a costly error. Otherwise, it should simply create a high-priority maintenance ticket.

Step 1: Define the Agent's Goal

In the agent configuration, we set its system prompt:

"You are an AI Predictive Maintenance Engineer for our CNC machines. Your primary objective is to prevent catastrophic failures and material waste. You are triggered when either vibration or temperature exceeds its warning level. When triggered, you must use the

getJobStatustool to check if the machine is running a 'High-Precision' job. If it is, you must use theemergencyStoptool immediately. If it is not a high-precision job, use thecreateWorkOrdertool to schedule maintenance."

Step 2: Configure the Agent's Tools

Using the visual editor, we grant the agent three specific tools:

-

Get Job Status (API Tool)

- Type:

API - URL:

https://erp.myfactory.com/api/v1/jobs/{{asset_id}} - Method:

GET - Description for AI: "Returns the current job details for a given machine asset ID."

- Type:

-

Emergency Stop (MQTT Tool)

- Type:

MQTT - Topic:

cnc/machines/{{asset_id}}/command - Payload:

{"command": "STOP"} - Description for AI: "Publishes an immediate stop command to the specified machine."

- Type:

-

Create Work Order (API Tool)

- Type:

API - URL:

https://mes.myfactory.com/api/v2/workorders - Method:

POST - Body:

{"asset_id": "{{asset_id}}", "description": "AI detected anomalous readings. Please inspect spindle.", "priority": "High"} - Description for AI: "Creates a high-priority maintenance work order in the MES."

- Type:

Step 3: Set the Trigger

We configure the agent to be of type Autonomous and set its trigger to be an MQTT topic: cnc/machines/+/telemetry. This means any message published to this topic pattern will activate the agent.

Step 4: The Autonomous Workflow in Action

Let's see what happens when the following message is published to cnc/machines/cnc-101/telemetry:

{

"timestamp": "2024-06-18T10:00:00Z",

"asset_id": "cnc-101",

"vibration": 0.78,

"temperature": 95.5

}

- Trigger: The agent is activated by the message. The JSON content becomes its initial context.

- Reasoning (Goal Analysis): The agent's AI core processes its goal. It recognizes it has been triggered by sensor data and its first step is to check the job status.

- Tool Use (1): It identifies the

getJobStatustool as the correct one for this task. It extractscnc-101from the incoming data and populates theasset_idvariable in the tool's URL. It makes the API call tohttps://erp.myfactory.com/api/v1/jobs/cnc-101. - Data Ingestion: The ERP system responds with:

{"job_id": "J-9876", "job_type": "High-Precision", "material": "Titanium-Grade5"}. This response is fed back into the agent's context. - Reasoning (Decision): The agent now has all the information. The trigger data is anomalous, and the job type is "High-Precision". It consults its goal again and determines it must use the

emergencyStoptool. - Tool Use (2): It invokes the

emergencyStoptool, publishing{"command": "STOP"}to the topiccnc/machines/cnc-101/command. - Conclusion: The machine stops safely, preventing a potentially ruined titanium part worth thousands of dollars. The agent logs its final action: "Executed emergency stop on cnc-101 due to anomalous sensor readings during a high-precision job."

If the job type had been "Rough-Cutting", the agent would have instead chosen the createWorkOrder tool, allowing production to continue while flagging the machine for inspection. This nuanced, context-aware decision-making is impossible with simple if-then rules.

Impact on Operational Excellence

Deploying a fleet of such agents has a transformative impact on the factory floor:

- Increased OEE (Overall Equipment Effectiveness): By preventing unplanned downtime (improving Availability) and reducing defects (improving Quality), agents directly contribute to a higher OEE score.

- Reduced Human Error: Agents execute standard operating procedures flawlessly every time, reducing variability and errors associated with manual interventions.

- Empowered Workforce: Rather than replacing human workers, agents augment them. Operators and engineers are freed from tedious monitoring and reactive firefighting, allowing them to focus on higher-level problem-solving, process improvement, and strategic initiatives.

- Enhanced Safety: Agents can monitor for unsafe conditions (e.g., gas leaks, missing safety guards on vision systems) and trigger shutdowns or alerts faster than humanly possible.

Conclusion

The Industrial IoT AI Agent is the logical and necessary evolution of Industry 4.0. It moves us from a paradigm of data collection to one of autonomous action and operational intelligence. By defining clear goals and providing agents with the right tools, you can create a digital workforce that collaborates with your human team to build a safer, more efficient, and more resilient factory of the future. Platforms like MQTTfy are making this a reality today, providing the no-code environment needed to rapidly design, deploy, and manage these powerful digital workers.