The Autonomous Factory: AI Agents for SCADA, Maintenance & Operations

January 13, 2026

The Dawn of the Autonomous Factory

The fourth industrial revolution (Industry 4.0) has moved beyond simple data collection and entered a new, more intelligent phase: the era of the autonomous factory. This is not a distant science-fiction concept but an emerging reality powered by the convergence of Industrial IoT (IIoT), advanced data analytics, and, most critically, specialized AI agents. These agents are digital workers, designed to perform specific roles traditionally held by humans—Maintenance Manager, Operations Supervisor, SCADA Analyst—but with the tireless precision and predictive power of artificial intelligence.

In this advanced guide, we will dissect the architecture and implementation of a modern autonomous factory floor, managed not by a single monolithic AI but by a team of collaborating AI agents. We will explore how platforms like MQTTfy enable the creation of these specialized agents and how they interact with existing industrial systems like SCADA, MES, and ERPs to drive unprecedented levels of efficiency, safety, and productivity.

Rethinking the Factory Floor: From Silos to a Collaborative AI Team

Historically, factory operations have been managed in silos. The maintenance team responds to breakdown alerts, the operations team monitors production quotas, and SCADA engineers watch over the control systems. While effective, this model is inherently reactive and prone to information gaps. The autonomous factory dismantles these silos by creating a digital nervous system where specialized AI agents act as the neurons, each with a distinct function but all interconnected and sharing information.

Let's define the key players in our autonomous factory team:

- The Maintenance Manager AI Agent: Its primary goal is to maximize equipment uptime and transition from reactive to predictive maintenance. It constantly analyzes vibration, temperature, and power consumption data to predict failures before they happen.

- The Operations Supervisor AI Agent: This agent is focused on production efficiency. Its goal is to meet production targets while optimizing resource usage. It monitors production counts, material flow, and cycle times, making real-time adjustments or alerting human counterparts to bottlenecks.

- The SCADA Analyst AI Agent: Acting as the central nervous system's watchdog, this agent monitors the Supervisory Control and Data Acquisition (SCADA) system's event logs. It identifies abnormal patterns, correlates alarms across different systems, and can even initiate automated root cause analysis.

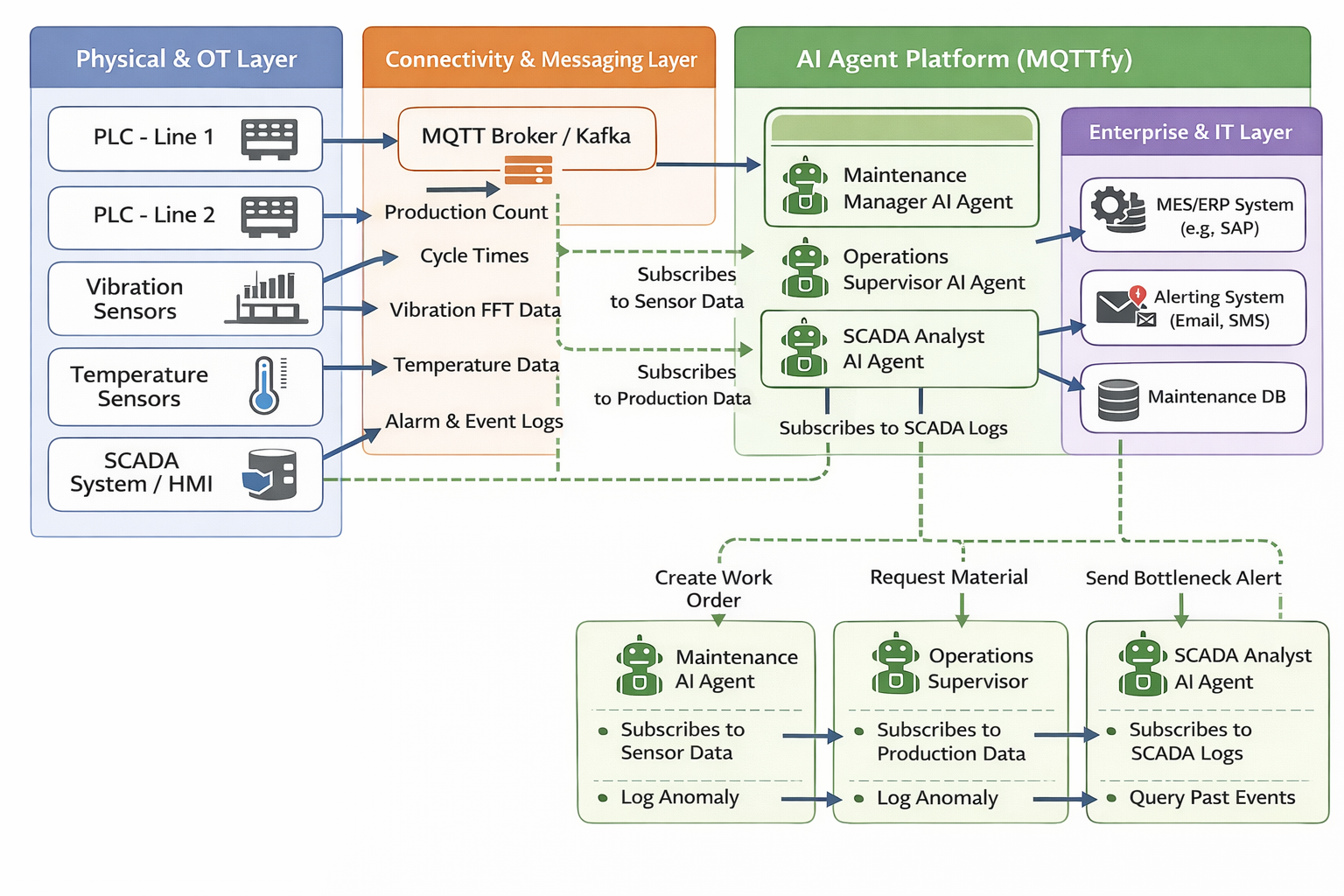

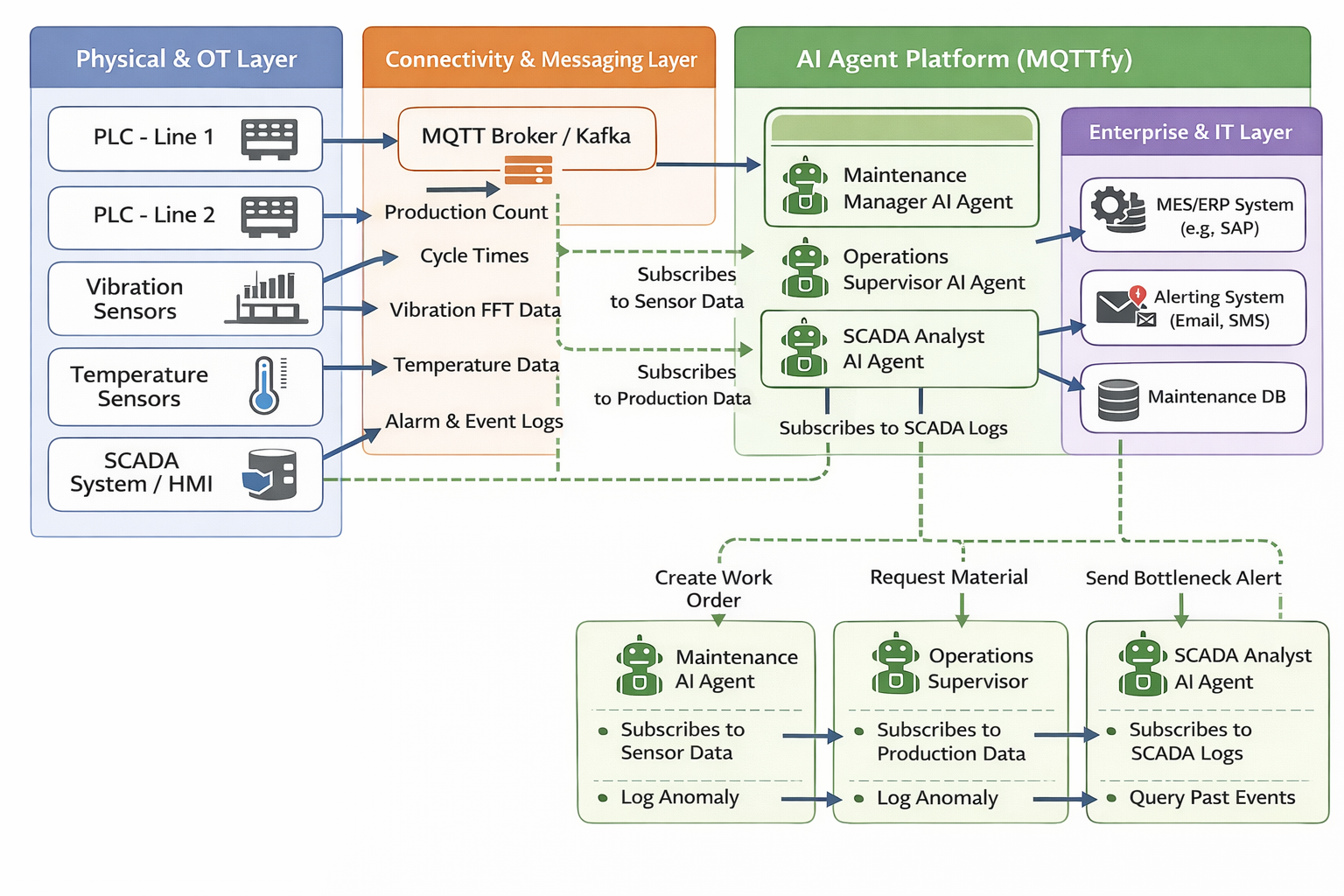

The Architectural Blueprint

A successful autonomous factory relies on a robust and scalable architecture. The diagram below illustrates a typical implementation where these specialized agents collaborate.

This architecture highlights a crucial principle: decoupling. The physical devices (OT Layer) publish data to a central messaging bus without needing to know who or what will consume it. The AI agents subscribe to the data streams relevant to their specific roles, process the information, and then interact with higher-level enterprise systems.

Implementing the AI Agents: A Practical Guide

Let's delve into how each agent is built and configured using a platform like MQTTfy's Agent Studio. Each agent is defined by its Goal (its system prompt) and the Tools it has at its disposal.

1. The Maintenance Manager AI Agent

Goal: "You are an AI Maintenance Manager. Your primary goal is to prevent unplanned downtime. Continuously analyze incoming vibration and temperature data. If you predict an impending failure based on rising trends or anomalies, use the 'Create Work Order' tool to automatically schedule a maintenance inspection in the MES. Your analysis should be based on comparing the last 10 data points against the historical average."

Tools:

- MQTT Subscriber: Listens to topics like

sensors/line1/motor/vibrationandsensors/line1/motor/temperature. - MES/ERP Connector (API Tool): A tool configured to make a

POSTrequest to the manufacturing execution system's API endpoint for creating work orders (e.g.,/api/workorders). - Maintenance Database (SQL Tool): A tool to

INSERTanomaly data into amaintenance_logstable for future analysis.

Example Workflow (triggered by new vibration data):

- The agent receives a new vibration reading:

{"value": 0.8, "unit": "g"}. - The agent's internal logic (or a dedicated "AI Analysis" tool) queries its short-term memory of the last 10 readings for this sensor.

- It compares the current value and recent trend against a pre-calculated historical baseline for this motor.

- The AI core determines that the vibration has increased by 30% over the last hour, exceeding a predictive threshold.

- It invokes its MES/ERP Connector tool, formatting a request body like:

{"asset_id": "L1-Motor-A", "issue_description": "AI Detected abnormal vibration trend. Please inspect.", "priority": "Medium"}. - It then uses its Maintenance Database tool to execute the SQL command:

INSERT INTO maintenance_logs (asset_id, log_time, value, type) VALUES ('L1-Motor-A', NOW(), 0.8, 'vibration'); - The final output of the agent run is a log: "Vibration anomaly detected on L1-Motor-A. Work order created and event logged."

2. The Operations Supervisor AI Agent

Goal: "You are an AI Operations Supervisor responsible for meeting a target of 500 units per hour. Monitor the production count and cycle time data. If the production rate falls below the target for more than 10 minutes, identify the bottleneck by comparing the cycle times of different line sections. Use the 'Send Alert' tool to notify the human supervisor of the specific bottleneck. If inventory levels are the issue, use the 'Request Material' tool."

Tools:

- MQTT Subscriber: Listens to

line1/production_countandline1/section_*/cycletime. - Alerting Tool (Email/SMS): A tool configured to send messages to specific recipients.

- MES/ERP Connector (API Tool): A tool with access to inventory and material request endpoints.

Example Workflow (triggered by a low production count):

- The agent receives a production count update, and its internal state tracker notes that the rate has been below 500 units/hour for 11 minutes.

- The AI core decides action is needed. It analyzes the recent data from all

line1/section_*/cycletimetopics. - It identifies that

line1/section_3/cycletimehas spiked by 50%, while other sections remain normal. - It invokes its Alerting Tool with the message:

"Production on Line 1 is below target. Bottleneck detected at Section 3 (Packaging). Current cycle time is 52 seconds (Target: 35s).". - The final output is logged: "Alert sent for bottleneck at Section 3."

3. The SCADA Analyst AI Agent

Goal: "You are an AI SCADA Analyst. Your role is to find meaningful patterns in system alarms. Monitor the SCADA event log stream. If a 'Compressor High Pressure' alarm is followed by a 'Pump Shutdown' alarm within 60 seconds from the same facility area, correlate these events. Use the 'Query Historian' tool to retrieve pressure data for the 5 minutes preceding the event. Summarize your findings and use the 'Create Report' tool to send a high-priority correlated event report."

Tools:

- MQTT/Kafka Subscriber: Listens to the

scada/alarms/eventstopic. - Historian Connector (SQL/API Tool): A tool configured to query the plant's data historian.

- Reporting Tool (Email/API): A tool to generate and send formatted reports.

Example Workflow (triggered by a "Pump Shutdown" alarm):

- The agent receives the

Pump Shutdownalarm for Area B. - It checks its short-term memory and finds a

Compressor High Pressurealarm from Area B that occurred 45 seconds prior. The condition is met. - The AI core invokes the Historian Connector tool with a query like:

SELECT value, timestamp FROM pressure_readings WHERE tag='comp_b_pressure' AND timestamp BETWEEN '2024-06-15T10:25:00Z' AND '2024-06-15T10:30:00Z'. - The historian returns the data, showing a rapid pressure spike.

- The agent synthesizes this information and uses its Reporting Tool to generate a summary:

"Correlated Event Detected in Area B: Compressor High Pressure alarm at 10:29:15 led to a Pump Shutdown at 10:30:00. Historian data confirms pressure spiked from 90 PSI to 150 PSI in the 30 seconds before shutdown. Recommended action: Inspect compressor relief valve." - The report is sent, and the agent's run is logged.

The Future is Collaborative and Autonomous

Building an autonomous factory is not about deploying a single, all-knowing AI. It's about creating a team of specialized, collaborative digital workers. Each AI agent, with its specific goal and curated set of tools, becomes an expert in its domain.

By leveraging platforms that allow for this granular, role-based creation of agents, industries can move from a state of passive data collection to one of active, intelligent, and autonomous operations. The Maintenance Manager, Operations Supervisor, and SCADA Analyst AI agents are just the beginning. As connectivity and AI capabilities grow, we will see entire factories run by swarms of these digital agents, working in concert with their human counterparts to achieve new frontiers of industrial excellence.